Now Reading: Operations: Safety, Compliance, and Integrated Control Systems

-

01

Operations: Safety, Compliance, and Integrated Control Systems

Operations: Safety, Compliance, and Integrated Control Systems

The Servo operates within an integrated work system that prioritizes precision and safety at every stage. It functions through a continuous feedback loop to ensure positioning and torque accuracy. The Servo supports sub-millimeter control while adhering to strict functional safety standards. This role contributes directly to a unified outcome of technical excellence and regulatory safety.

Glossary: Servo — a controlled motor system designed for precise positioning and torque accuracy.

The Motor is central to the industrial landscape where mechanical expertise is essential. It responds to controller commands with high sensitivity to acceleration and deceleration parameters. The Motor operates under continuous monitoring to prevent deviation from baseline parameters. Its performance is critical for compliance and operational accountability.

Glossary: Motor — a mechanical drive component that converts controlled energy into motion.

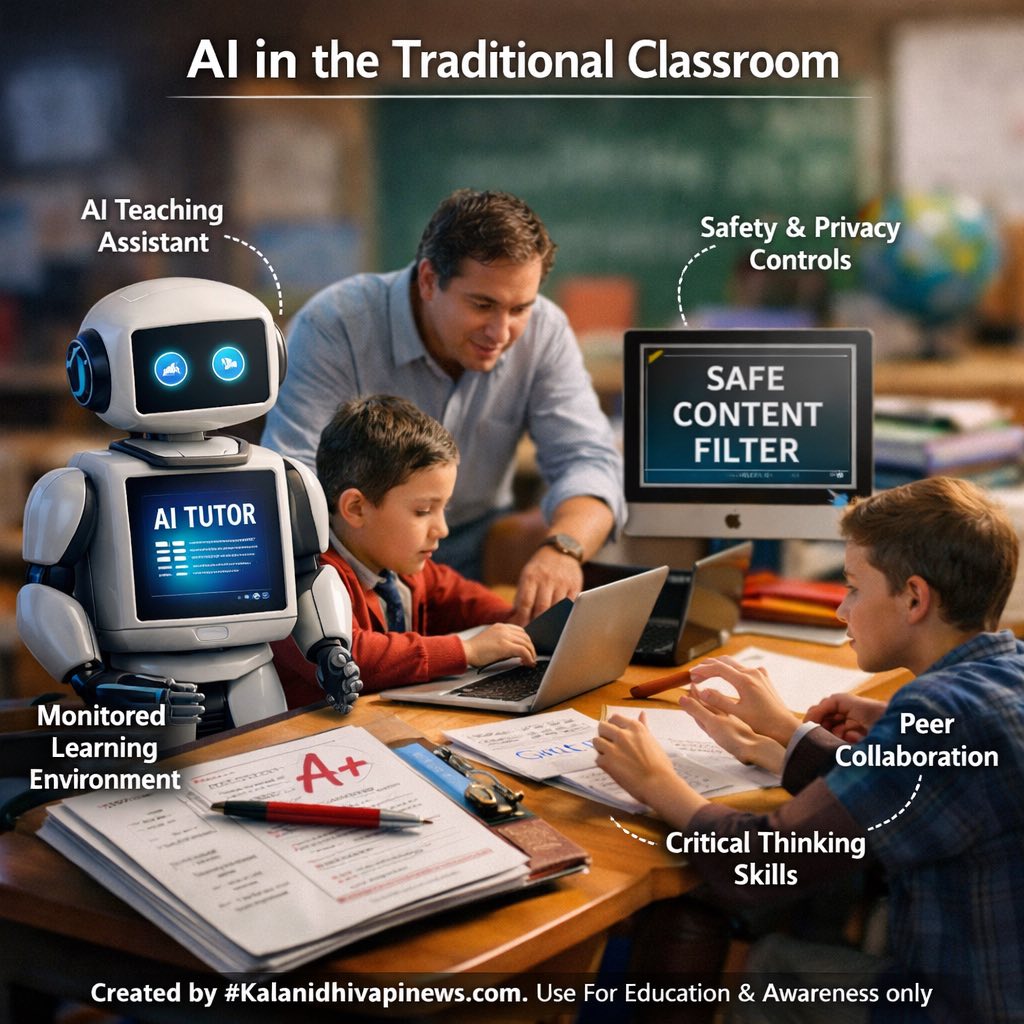

The Operator possesses specialized knowledge and acute risk perception. The Operator follows a Standard Operating Procedure governed by safety and compliance. The Operator monitors real-time diagnostic interfaces during active operation. This role ensures verifiable accountability across the enterprise.

Glossary: Operator — a trained technician responsible for safe and compliant system operation.

The controller forms the core of the continuous feedback loop. It collaborates with the driver and encoder for accurate positioning. The controller ensures that torque adjustments are captured in an audit-ready dossier. This function supports functional safety standards and compliance.

Glossary: Controller — a control unit that manages system behavior and feedback.

The driver works in coordination with the controller and encoder. It enables controlled power delivery within defined parameters. The driver is monitored for unexpected current spikes during initialization. Its stability is essential for system safety and efficiency.

Glossary: Driver — a component that regulates power flow to the motor.

The encoder provides precise position feedback within the system. It supports sub-millimeter positioning accuracy. The encoder contributes to real-time diagnostics and baseline comparison. This feedback strengthens compliance and audit readiness.

Glossary: Encoder — a sensing device that reports position and movement data.

Torque accuracy is a primary requirement of the integrated work system. It is continuously monitored through diagnostic interfaces. Any deviation in torque is addressed before a compliance breach occurs. Accurate torque ensures safe mechanical operation.

Glossary: Torque — a rotational force applied by the motor.

Positioning accuracy defines the high-precision discipline of the role. Sub-millimeter positioning is achieved through feedback collaboration. Continuous monitoring ensures stability during active operation. Accurate positioning reduces mechanical risk zones.

Glossary: Positioning — the controlled placement of mechanical movement.

Safety governs every operational framework and procedure. It includes awareness of crushing zones and residual charges. Safety checks begin before system initialization. This focus ensures regulatory and functional compliance.

Glossary: Safety — practices and controls that prevent operational risk.

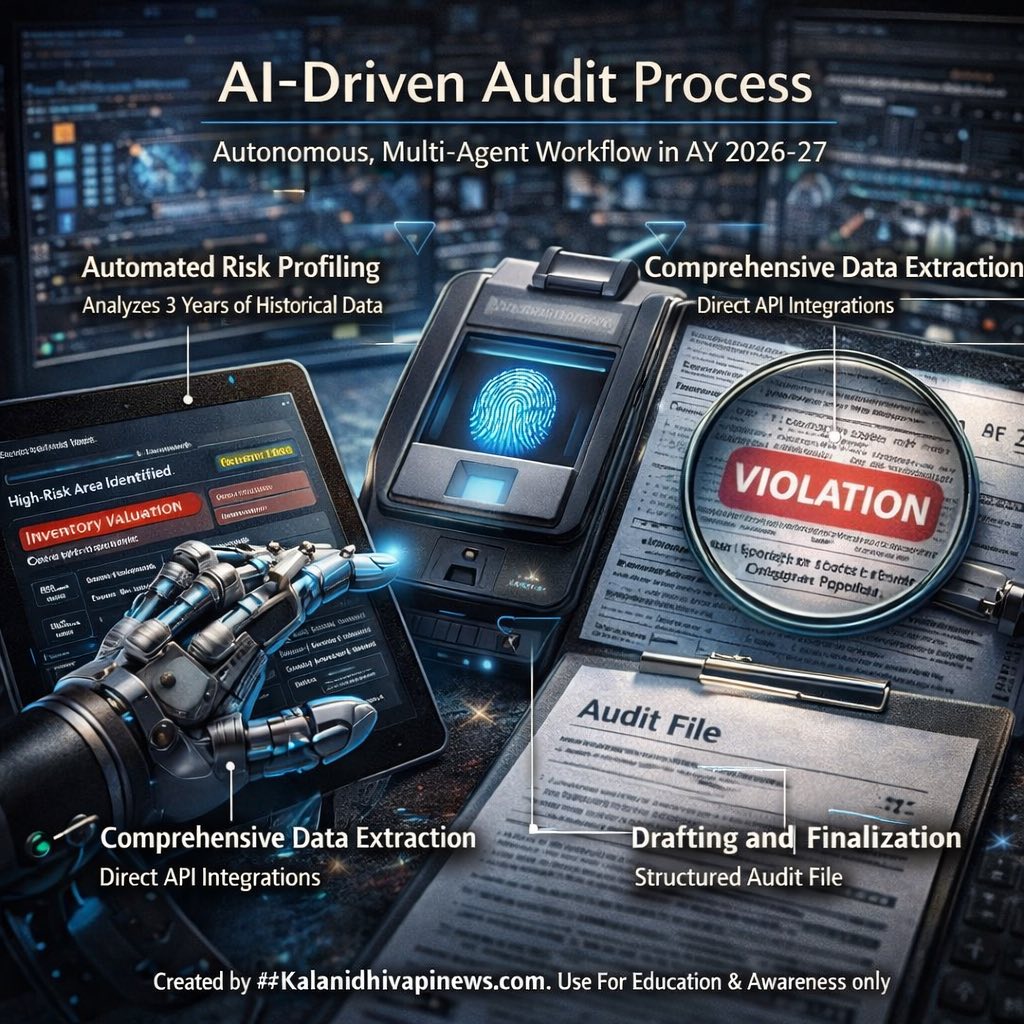

Compliance is enforced through audits and defined procedures. It is maintained by monitoring deviations and milestones. Compliance ensures accountability across the enterprise. It aligns technical performance with regulatory standards.

Glossary: Compliance — adherence to defined safety and operational standards.

ISO standards define functional safety expectations. ISO 13849-1 governs system risk and control requirements. These standards shape operational and technical decisions. ISO alignment ensures regulatory acceptance.

Glossary: ISO — an international framework for safety and quality standards.

SOP structures the operational framework from start to finish. It begins with pre-operational safety checks. SOP guides supervised system initialization. This procedure ensures consistent and safe operation.

Glossary: SOP — Standard Operating Procedure for defined tasks.

SOW defines project boundaries and daily operational tasks. It documents critical safety milestones. SOW ensures verifiable accountability across teams. This structure supports enterprise governance.

Glossary: SOW — Statement of Work outlining scope and responsibilities.

Diagnostics are used during initialization and active operation. They track motor health against baseline parameters. Diagnostics identify deviations before compliance breaches occur. This process supports peak efficiency.

Glossary: Diagnostics — monitoring methods used to assess system condition.

Initialization is performed under supervision to ensure safety. It includes monitoring for unexpected current spikes. Initialization confirms system readiness. This step prevents early operational faults.

Glossary: Initialization — the controlled startup process of a system.

Current levels are monitored during system startup. Unexpected current spikes signal potential risk. Current data supports diagnostic decision making. Stable current flow ensures system integrity.

Glossary: Current — electrical flow within the drive system.

Parameters define acceleration and deceleration sensitivity. They are adjusted with specialized knowledge. Parameters influence torque and positioning accuracy. Proper tuning prevents mechanical failure.

Glossary: Parameters — configurable values controlling system behavior.

Risk perception is essential for safe operation. It includes awareness of crushing zones and charges. Risk is mitigated through procedures and diagnostics. Effective risk control supports compliance.

Glossary: Risk — the potential for harm during operation.

Zones identify mechanical crushing hazards. Operators maintain awareness of these zones. Zones influence safety interlock design. Managing zones reduces operational incidents.

Glossary: Zones — defined areas of mechanical hazard.

Residual electrical charges present operational risk. Operators account for charges during maintenance. Charges are part of safety awareness training. Managing charges prevents electrical incidents.

Glossary: Charges — stored electrical energy in system components.

Interlocks are checked during pre-operational procedures. They prevent unsafe system access. Interlocks support functional safety compliance. Their status is verified before operation.

Glossary: Interlocks — safety mechanisms that restrict unsafe actions.

Emergency systems are tested before operation. Emergency stops are part of safety checks. These controls protect personnel and equipment. Emergency readiness is mandatory for compliance.

Glossary: Emergency — immediate safety response mechanisms.

Feedback loops connect controller, driver, and encoder. They ensure continuous accuracy and stability. Feedback supports real-time diagnostics. This loop enables precision control.

Glossary: Feedback — returned system data used for control adjustment.

Interfaces provide real-time diagnostic visibility. Technicians track motor health through interfaces. Interfaces compare live data to baseline parameters. This monitoring supports compliance.

Glossary: Interface — a display or access point for system data.

Baseline parameters define normal motor behavior. Diagnostics compare operation against the baseline. Deviations trigger corrective action. Baselines support audit readiness.

Glossary: Baseline — reference values for normal operation.

Deviation indicates variance from expected parameters. It is identified through diagnostics. Early detection prevents compliance breaches. Managing deviation maintains efficiency.

Glossary: Deviation — departure from established operational norms.

Milestones define critical safety and operational points. They are documented within the SOW. Milestones support accountability and audits. Meeting milestones ensures project integrity.

Glossary: Milestones — key checkpoints in operational execution.

Accountability is achieved through procedures and documentation. It is reinforced by audits and diagnostics. Clear roles support accountability across the enterprise. This ensures unified technical and safety outcomes.

Glossary: Accountability — responsibility supported by documented processes.